Housekeeping & Operation of DR-OS Hadeed

Housekeeping & Operation of DR-OS Hadeed

Altema contracting & Industrial services performed under this Contract is to supply skilled and professional manpower to carry out the Operation Support Services at HADEED Direct Reduction Plants (A,B,C,D,E) in an efficient and systematic manner without interruption of any nature.

Housekeeping: To carryout required housekeeping intensively, collecting spilled raw materials and pellets, solid waste/by product and shift it to designated area containment, cleaning and maintaining the process lines and roads. Work locations is under the DR Operation Support Section (Module AB,C,D & E), which includes, but is not limited to, stockyard rails, stackers, underground tunnels, DR Plant product route, mesh and chutes. Tools and tackles used include, but are not limited to, pneumatic air, shovels, brushes, brooms etc. Housekeeping labors needs the ability to read safety and work instructions, sign boards, identifying job hazards and reporting to immediate supervisors etc.

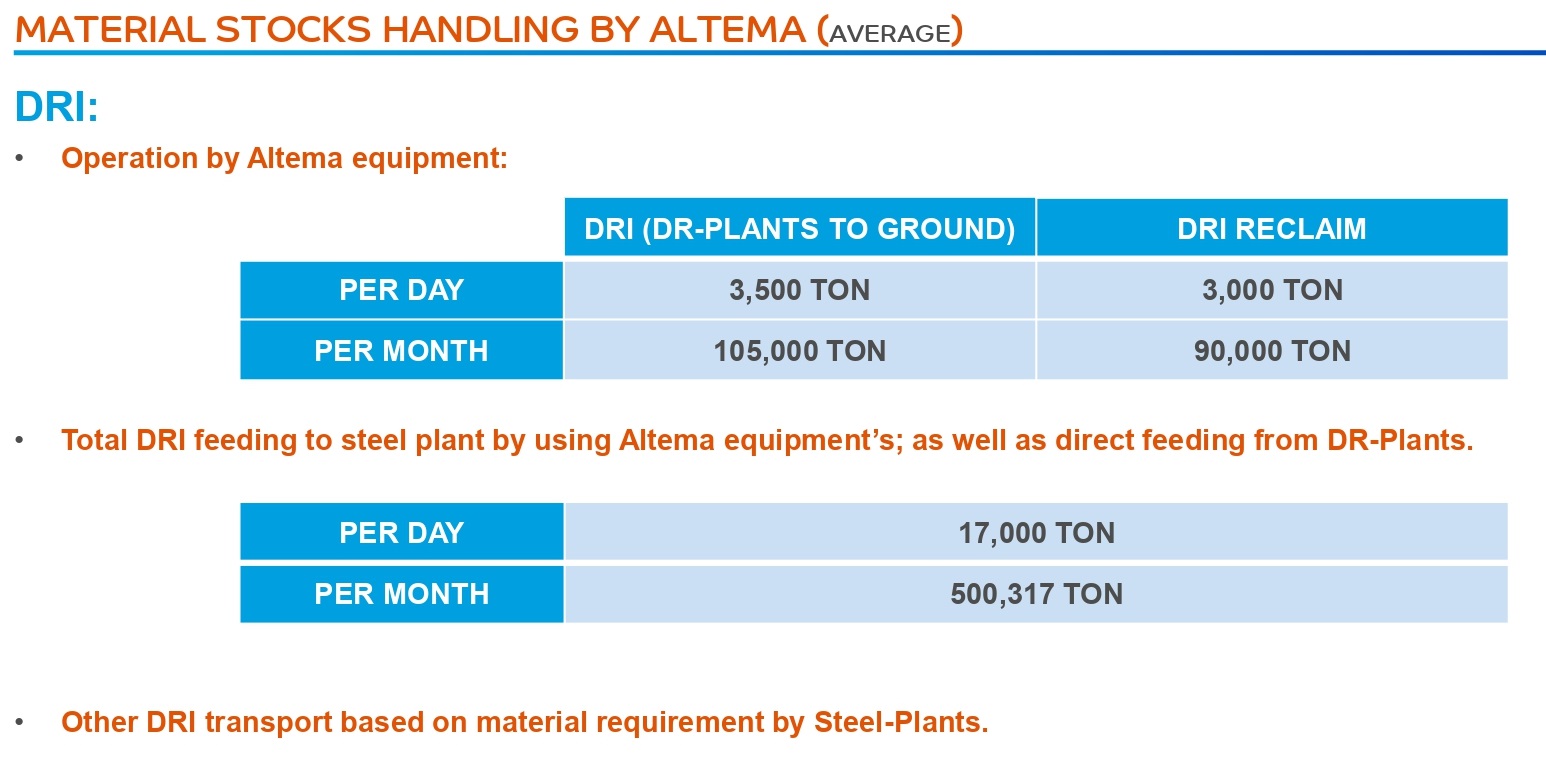

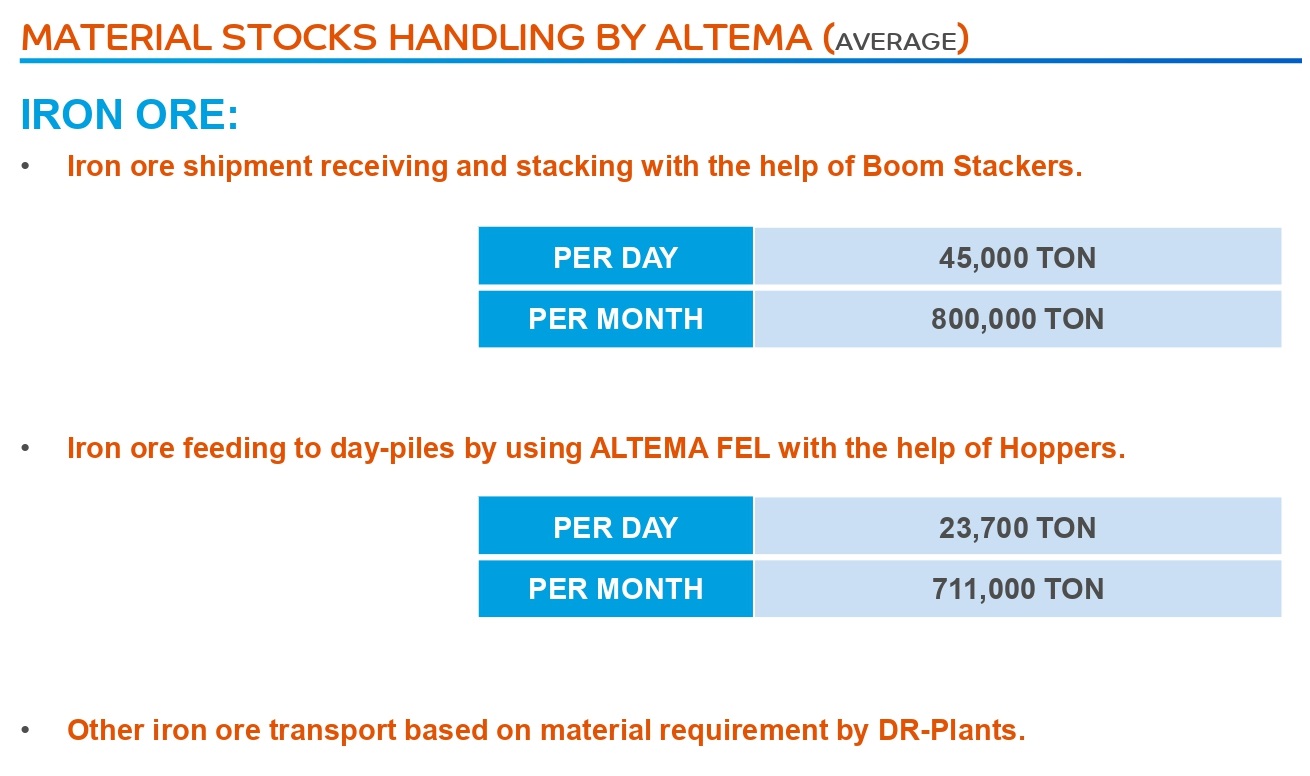

Operation: Performs operating functions in one of designated areas of work, namely: stacker ABC , D & E operation in the ore stockyard, and the internal conveyor feed/discharge systems. Operates a boom stacker in the Hadeed ore stockyard, maintaining a steady, continuous flow of ore onto the appropriated pile. Adjusts boom height to provide constant stack height. Watches to detect tramp material, initiates action to remove as soon as practical. Switches operation to local control on failure of the automatic system. Cleans and leaves the stacker in a safe condition at the end of his duty

- Performs operating functions in one of designated areas of work, namely: Cement Mixer C , D & E : To inspect feed and maintain clean, organized area and report cement levels in DR plants Performs operating functions in the Module E operation in the Oxide & Product Route.

- Operates items on local control as required; conveyors, visually checking for equipment defects, and takes corrective action to remove chokes, spillages or to request maintenance assistance.

- Patrols the internal conveyor systems feeding the DR Plant and discharge to the Steel Plant Silos. Visually inspect for steady operation, clears chokes and spillages immediately they occur. Resets stops and starts sections of belt as necessary. Listens for abnormal running noises, is watchful for rising temperatures giving indication of potential fire, and keeps a regular communication with supervisor. Normally performs any related cleaning or laboring function associated with the movement of iron oxide or product, as directed by the shift supervisor, especially in the case of urgent or emergency need. Assigned area of work shall be visited and inspected minimum of three times per shift based on plant condition.